Starting adjustment procedure for paver:

At the beginning, it is necessary to set the machine, that is, to calibrate various parameters.

You need to know the unit data, which is how many numbers to walk or how many turns to turn on the 1cm chart.

Is the water stable or the oil layer? If the water is stable, adjust it to 4-5cm, then walk 2-3m and observe before adjusting. If it is an oil layer, adjust it in units of 1cm.

Most of them rely on experience judgment, such as paving thickness, pad thickness, paving materials, elevation height, and different adjustments for different working conditions.

Disclaimer | Some content is sourced from the internet! This article is for communication and learning purposes only. The copyright belongs to the original author. Some images and content were not promptly contacted when pushed. If the source annotation is incorrect or infringes on your rights, please inform us and we will immediately delete it

Company Introduction

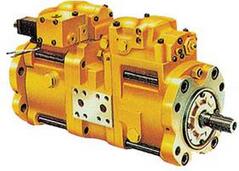

The company supplies paver accessories, roller accessories, milling machine accessories, paver scraper drive shaft, scraper drive shaft assembly, leveling instrument, leveling instrument bracket, hydraulic pump and accessories. We also supply vulnerable parts for pavers, including balance beams, agitator shafts, pedals, feeding base plates, blades, ironing plates, reducers, chain rails, track plates, support wheels, scraper chains, and feeding chains.

Contact: Manager Liang

Contact information: 13645201509 (same WeChat account)

QQ:2870202745

QQ email: 2870202745@qq.com

NetEase email: LS13645201509@163.com

WhatsApp:+86 13645201509